Educations

5S Training

With 5S applications, more regular, cleaner and cleaner work areas are created, costs are reduced, productivity is increased, job security and motivation are ensured. The aim of 5S, which is the basis of lean production practices and is called as workplace organization, is to make the material and information flow in the workplace fast and accurate by creating a cultural change.

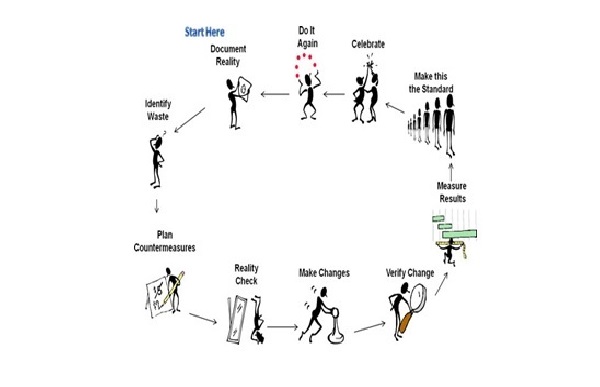

Kaizen Training

KAIZEN means the continuous improvement, which is formed by the combination of the kai in Japanese and the words in the meaning of zen better. The first objective is to improve the process with small but effective changes

6 Sigma Training

6 Sigma is based on customer satisfaction. It is a methodology developed to reduce the error rate to zero in business processes, to increase productivity, to find factors affecting business process, to provide rapid improvement and to bring customer satisfaction to the highest level.